Rotary Hybrid Stepper Motors

Small Size with High Torque and Superior Response

Nippon Pulse’s hybrid stepper motor is ideal for motion control applications where the benefits of smaller size with high torque are essential. The hybrid motors feature superior response characteristics and function in a wide variety of applications.

Specification Overview

- Available in NEMA size 8 (20mm) to NEMA size 34 (86mm)

- Holding torque between 0.022 and 8.2 Nm

- 200 steps per revolution with step angle of 1.8⁰

- Unipolar and bipolar windings

- Customization options available on all hybrid steppers

- Optional encoder feedback (1000, 2500 ppr)

Rotary Hybrid Stepper Motor Advantages

- Easily determined and controlled speed (speed = steps per revolution /pulse rate)

- Fine incremental moves without requiring a feedback encoder (open loop)

- Optional encoder for servo stepper performance (closed loop)

- Fast acceleration with non-cumulative positioning error

- Low speed/high torque characteristics without gear reduction

- Loads held in a stationary position without creating overheating

- Wide speed range

Precision Solutions for Industries

- Packaging

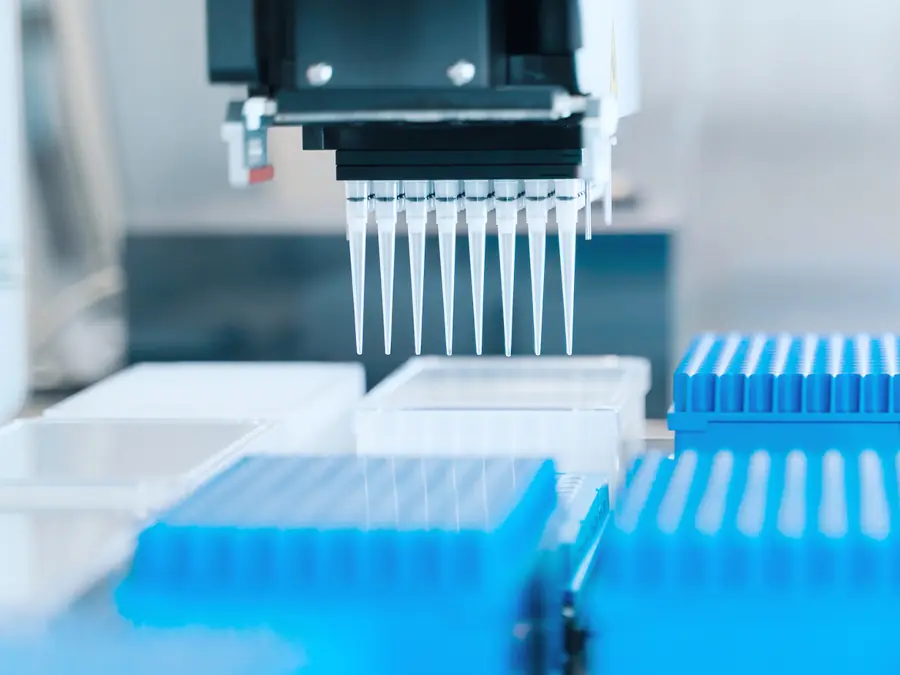

- Life Sciences

- Semiconductor

- Optics & Photonics

- Robotics

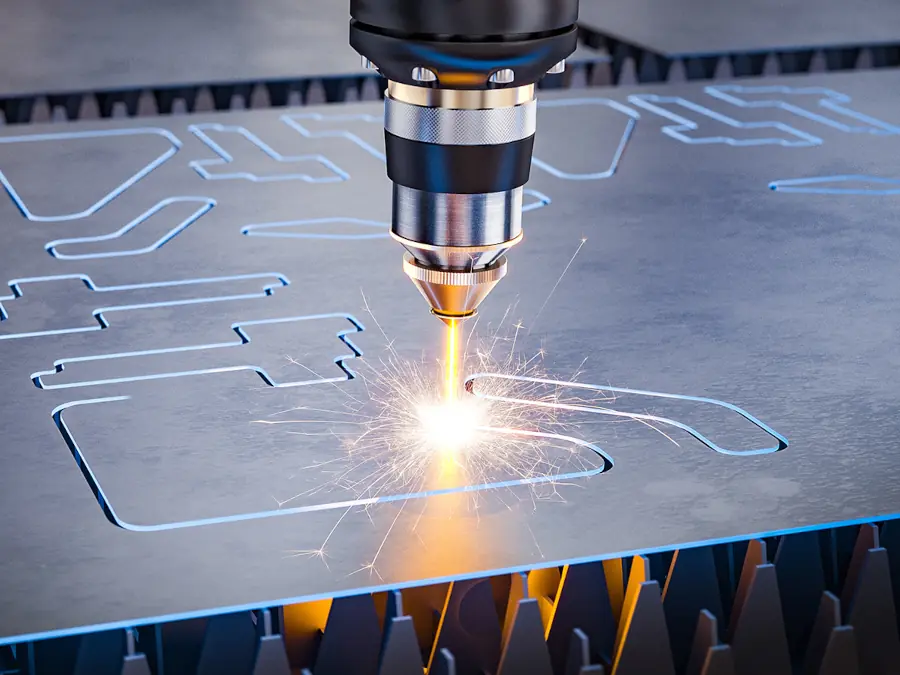

- Toolless Cutting

- Lab Automation

- Pharmaceuticals

Select the Best Rotary Hybrid Stepper Motor for your Application

1. Outline the motions that are required for the application

2. Determine the acceleration, traverse, and deceleration times needed for each movement

3. Calculate the torques needed to move the payload based on the desired motion profile

4. Find a coil with a torque curve that provides more than the required torque at each speed in the move profile to move the payload

5. Select the correct electronics needed to drive the motor